Features

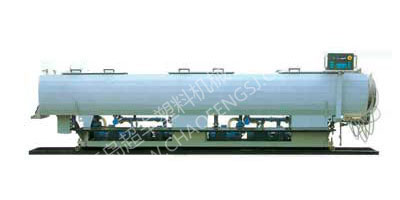

The new high-efficiency single-screw plastic extruder developed by our company introduces the latest technology from Germany. The screw adopts the optimized composition of the separating screw and the mixing component. The barrel adopts the optimized design of the grooved barrel and the extended feeding section. Through the combination of a split screw and a grooved barrel, the following advantages can be obtained:

The melting process of the material is optimized to increase extrusion throughput.

The extrusion of the material melt at a lower temperature is achieved.

The material is well homogenized by the shear action determined in the isolation gap.

The melt plasticization process is controlled, that is, only particles smaller than the isolation gap can enter the melt channel.

It provides a wide range of processing for different materials and is suitable for various polyolefin raw materials, especially suitable for HDPE, PP and ABS pipe materials.

Main technical parameters of pipe extrusion

Model | HX1-45-33B | HX1-60-33B | HX1-75-33B | HX1-90-33B | HX1-120-33B | HX1-150-33B |

Transmission power (kw) | 37 | 75 | 110 | 160 | 280 | 400 |

Screw diameter (mm) | 45 | 60 | 75 | 90 | 120 | 150 |

Number of screws | 33 | 33 | 33 | 33 | 33 | 33 |

Screw torque Nm | 1600 | 3600 | 6300 | 11200 | 25000 | 45000 |

Extrusion amount PVC HDPE/MDPE pellets (kg/h) PP pellets (kg/h | 150 110 | 300 200 | 450 320 | 600 450 | 1000 750 | 1300 900 |

Length x width x height | 2200x1440x1950 | 3000x1440x2000 | 3660x1550x2200 | 4230x1675x2200 | 5370x1860x2400 | 6630x1920x2450 |

Next:Wood plastic crust foam board production line